Subaru Legacy BN/BS (2015-2019) Service Manual: Dtc p2747 intermediate shaft speed sensor "b" circuit no signal

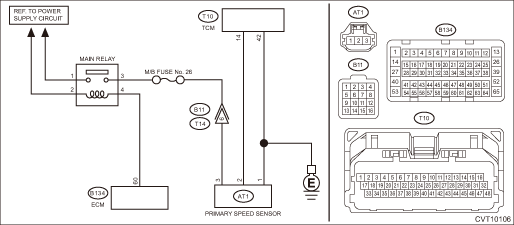

DTC DETECTING CONDITION: Immediately at fault recognition TROUBLE SYMPTOM: • Standing start problems • Shock occurs when engaging the lockup clutch. • Shock occurs when selecting shift position. 1. ENGINE TYPE FB WIRING DIAGRAM: CVT control system CVT Control System > WIRING DIAGRAM

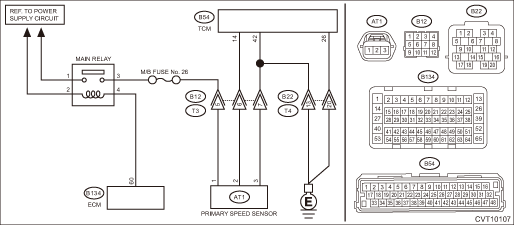

2. ENGINE TYPE EZ WIRING DIAGRAM: CVT control system CVT Control System > WIRING DIAGRAM

3. OUTLINE OF DIAGNOSIS (ENGINE TYPE FB) • Detect no input signal from the primary speed sensor. • Judge as NG if there is no input signal from the primary pulley speed sensor, while the secondary pulley speed sensor has the input signal although the primary and secondary pulleys are interlocked via the chain. 4. EXECUTION CONDITION (ENGINE TYPE FB)

5. DIAGNOSTIC METHOD (ENGINE TYPE FB) If the duration of time while the following conditions are met is longer than the time indicated, judge as NG.

Time Needed for Diagnosis: 0.5 seconds Malfunction Indicator Light Illumination: Illuminates as soon as a malfunction occurs. 6. OUTLINE OF DIAGNOSIS (ENGINE TYPE EZ) • Detect no input signal from the primary speed sensor. • Judge as NG if there is no input signal from the primary pulley speed sensor, while the secondary pulley speed sensor has the input signal although the primary and secondary pulleys are interlocked via the chain. 7. EXECUTION CONDITION (ENGINE TYPE EZ)

8. DIAGNOSTIC METHOD (ENGINE TYPE EZ) If the duration of time while the following conditions are met is longer than the time indicated, judge as NG.

Time Needed for Diagnosis: 0.5 seconds Malfunction Indicator Light Illumination: Illuminates as soon as a malfunction occurs. |

Dtc p2750 intermediate shaft speed sensor "c" circuit range/performance

Dtc p2750 intermediate shaft speed sensor "c" circuit range/performance

DTC DETECTING CONDITION:Immediately at fault recognitionTROUBLE SYMPTOM:• Shifting shock is felt.• Acceleration is poor during standing start.• Shift control malfunction1. ENGINE TYP ...

Dtc p2746 intermediate shaft speed sensor "b" circuit range/performance

Dtc p2746 intermediate shaft speed sensor "b" circuit range/performance

DTC DETECTING CONDITION:Immediately at fault recognitionTROUBLE SYMPTOM:• Standing start problems• Shock occurs when engaging the lockup clutch.• Shock occurs when selecting shift po ...

Other materials:

Installation

1. Install the auto headlight beam leveler CM.Tightening torque:7.5 N·m (0.8 kgf-m, 5.5 ft-lb)2. Install the relay holder.3. Install the panel - knee guard.Tightening torque:7 N·m (0.7 kgf-m, 5.2 ft-lb)4. Install the cover assembly - instrument panel LWR driver.5. Connect the ground te ...