Subaru Legacy BN/BS (2015-2019) Service Manual: Assembly

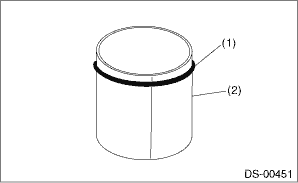

1. Roll up a thick piece of paper to a size where the shaft can pass through, and affix with tape to form a cylinder. 2. Attach a new O-ring on this cylinder. CAUTION: • Always use a new O-ring. • Be careful that the O-ring does not become scratched and that there are no foreign objects attached to it. • Make sure to install the O-ring so that it does not twist as much as possible. • Do not stretch the O-ring to 30 mm (1.18 in) inner diameter or more.

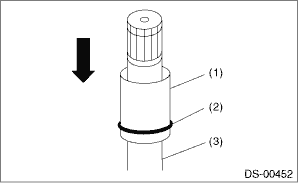

3. Pass the cylinder material onto the shaft, and slide in the direction of the shaft axis.

4. Clean the shaft boot groove, and wipe off the grease. 5. Slide the cylinder material near the shaft boot groove, and move the O-ring from the cylinder material onto the shaft boot groove. CAUTION: • Attach the O-ring to the shaft boot groove center. • Be careful that the O-ring does not become scratched and that there are no foreign objects attached to it. • Make sure to install the O-ring so that it does not twist as much as possible. • With the O-ring attached, do not wash with kerosene, gasoline, etc.

6. Pass the PTJ small diameter boot band through the shaft. 7. Wrap vinyl tape around the splines of the shaft. CAUTION: To prevent damage to the boots, make sure to always wrap with vinyl tape for protection. 8. Install a new PTJ boot. CAUTION: Make sure to fit securely on the boot groove of the shaft.

9. Match the alignment marks, and attach the trunnion onto the shaft.

10. Attach the snap ring to the shaft. CAUTION: Confirm that the snap ring is completely fitted in the shaft groove. 11. Fill 100 to 110 g (3.53 to 3.88 oz) of specified grease into the interior of the PTJ outer race. Grease: NKG302 12. Apply a thin coat of specified grease to the roller kit and trunnion. 13. Match the alignment marks of the roller kit and trunnion, and attach the roller kit. CAUTION: Be careful with the roller kit position.

14. Match the alignment marks of the shaft and outer race, and attach the outer race.

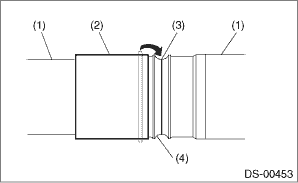

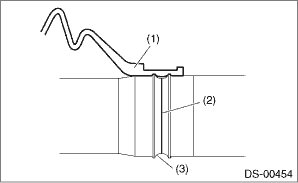

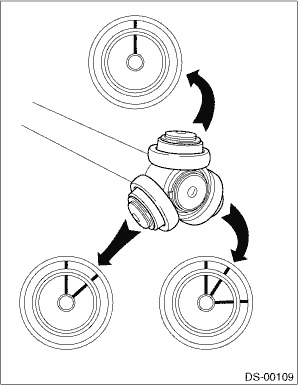

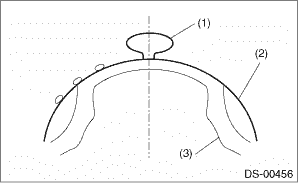

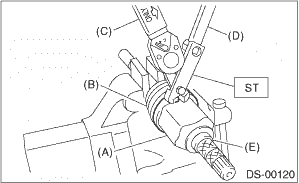

15. Install the snap ring in the groove of the PTJ outer race. CAUTION: Pull the shaft lightly and make sure that the snap ring is completely fitted in the groove. 16. Apply an even coat of the specified grease 30 to 40 g (1.06 to 1.41 oz) to the entire inner surface of boot. 17. Attach the PTJ boot taking care not to twist it. CAUTION: • Clean the large end of PTJ boot and the boot groove well, and remove the grease and other substances. • When installing the PTJ boot, position the outer race of the PTJ at center of the stroke. 18. Set the new boot band at the specified position. 19. Tighten the boot bands using ST, torque wrench and socket flex handle. CAUTION: The large boot band is to be tightened so that the omega shaped part is at the position indicated in the figure below.

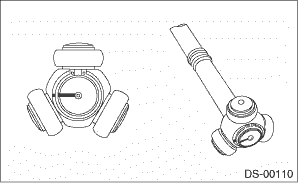

Tightening torque: Large boot band: 178 N·m (18.1 kgf-m, 131.3 ft-lb) Small boot band: 145 N·m (14.8 kgf-m, 106.9 ft-lb) Preparation tool: ST: BOOT BAND PLIERS (28099AC000)

20. Extend and retract the PTJ repeatedly so that grease is spread evenly. |

Removal

Removal

1. Lift up the vehicle, and then remove the front wheels.2. Remove the nut - axle.CAUTION:Do not loosen the nut - axle while the front axle is loaded. Doing so may damage the hub unit COMPL.(1) Lift t ...

Installation

Installation

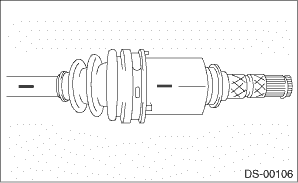

1. Before installation, check the drive shaft assembly. Front Drive Shaft > INSPECTION2. Replace the differential side retainer oil seal with a new part.• MT model: Differential Side Retainer ...

Other materials:

Power saving function

To protect the access key battery and the

vehicle battery, the keyless access function

will be disabled as follows.

When the keyless access function and

the remote keyless entry system have not

been used:

5 days after the push-button ignition

switch has been turned off, ...