Subaru Legacy BN/BS (2015-2019) Service Manual: Inspection

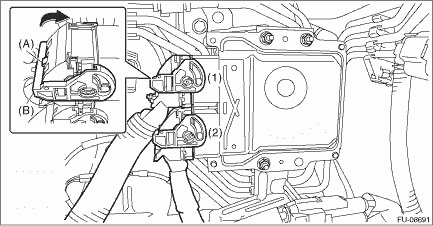

1. CRANKSHAFT POSITION SENSOR 1. Disconnect the ground terminal from battery sensor. NOTE 2. Prepare an oscilloscope. 3. While pressing the section (A) shown in the figure, move the lock lever (B) in the direction of the arrow to disconnect the connectors from the ECM in numerical order as shown in the figure.

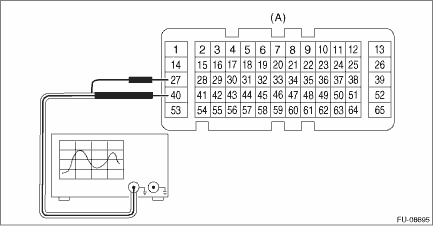

4. Attach the ST between the ECM, engine harness and the bulkhead wiring harness. General Description > CAUTION

5. Connect the probe to ST.

6. Start the engine and let it idle. 7. Check the waveforms and voltage. NOTE: For waveform and voltage, refer to “Engine Control Module (ECM) I/O Signal”. Engine Control Module (ECM) I/O Signal > ELECTRICAL SPECIFICATION 8. After inspection, install the related parts in the reverse order of removal. 2. OTHER INSPECTIONS Check that the crankshaft position sensor has no deformation, cracks or other damages. |

Removal

Removal

1. Remove the collector cover.(1) Carefully pull up the rear of collector cover at two positions (A).(2) Carefully pull up the front of collector cover at two positions (B) while moving it forward.2. ...

Installation

Installation

1. Install the crankshaft position sensor to the cylinder block, and connect the connector to the crankshaft position sensor.Tightening torque:6.4 N·m (0.7 kgf-m, 4.7 ft-lb)2. Install the servi ...

Other materials:

Operation

1. On «Start» display, select «Diagnosis».2. On «Vehicle selection» display, input the target vehicle information and select «Confirmed».3. On «Main Menu» display, select «Each System».4. On «Select System» display, select «EyeSight» and select «Enter».5. On «Select Function» dis ...