Subaru Legacy BN/BS (2015-2019) Service Manual: Inspection

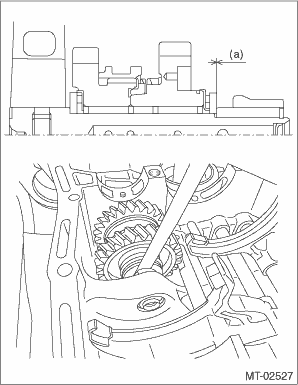

1. Check the clearance between the reverse idler gear bushing and reverse idler gear washer. If the value is out of specification, select the appropriate reverse idler gear bushing and adjust. Clearance (a): 0.1 — 0.3 mm (0.004 — 0.012 in)

2. Check the reverse idler gear and reverse idler gear shaft for damage. Replace if it is damaged. 3. Apply transmission gear oil to the cone of the reverse idler gear and while press-fitting the reverse baulk ring, check there is no rotation in the circumferential direction.

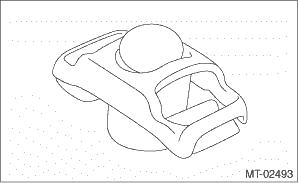

4. Reverse coupling sleeve and synchronizer hub • Check the sliding condition of the reverse coupling sleeve. • Check the splines on the reverse coupling sleeve and reverse idler gear for wear. 5. Reverse shifting insert Replace the reverse shifting insert if there is deformation, excessive wear on the ball section or any defectiveness.

|

Installation

Installation

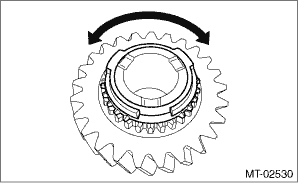

NOTE:Rotate the reverse idler sub gear by two teeth from free status in the direction of the arrow to make it engage with the reverse gear of the main shaft and install the main shaft assembly.(A)Free ...

Disassembly

Disassembly

1. REVERSE IDLER GEAR ASSY1. Remove the snap ring and friction plate.(A)Friction plate(B)Snap ring2. Remove the reverse idler sub gear and reverse idler spring.(A)Reverse idler sub gear(B)Reverse idle ...

Other materials:

Dtc b1577 imm control module eeprom

DIAGNOSIS START CONDITION:• Battery voltage is 10 V or more.• The remote engine starter was not used to start the engine.DTC DETECTING CONDITION:• Defective body integrated unit (except for C0 and C5 models) or immobilizer CM (C0 and C5 models)• Failed to access ROM in the bo ...