Subaru Legacy BN/BS (2015-2019) Service Manual: Intake manifold vacuum inspection

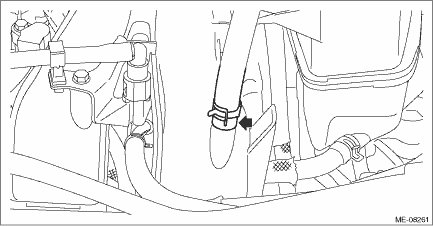

1. Warm up the engine. 2. Disconnect the brake booster vacuum hose from the intake manifold assembly.

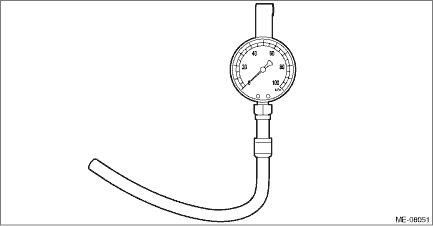

3. Connect the vacuum gauge to the installation area for the brake booster vacuum hose of the intake manifold assembly.

4. Keep the engine at idle speed and read the vacuum gauge indication. NOTE: Condition of engine inside can be diagnosed by observing the behavior of the vacuum gauge needle as described in table below. Intake manifold vacuum (at idling, A/C OFF): Standard −60.0 kPa (−450 mmHg, −17.72 inHg) or more

5. After inspection, install the related parts in the reverse order of removal. | ||||||||||||||

Intake and exhaust valve specification

Intake and exhaust valve specification

Refer to “Cylinder Head” for removal and installation procedures of the intake and exhaust valves. Cylinder Head > REMOVAL Cylinder Head > INSTALLATION ...

Piston specification

Piston specification

Refer to “Cylinder Block” for removal and installation procedures of pistons. Cylinder Block > REMOVAL Cylinder Block > INSTALLATION ...

Other materials:

Caution

• Wear appropriate work clothing, including a cap, protective goggles and protective shoes when performing any work.• Remove contamination including dirt and corrosion before removal, installation or disassembly.• Keep the disassembled parts in order and protect them from dust and ...