Subaru Legacy BN/BS (2015-2019) Service Manual: Assembly

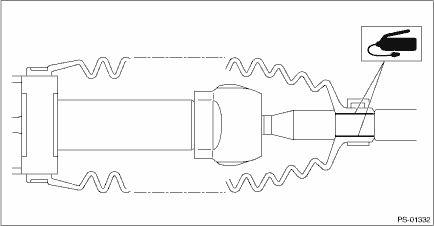

1. Install the tie-rod into rack. Tightening torque: 90 N·m (9.2 kgf-m, 66.4 ft-lb) NOTE: Check the mating face of rack and tie-rod for foreign matter such as dust etc. 2. Apply a coat of grease to the tie-rod groove, and then install the boot - steering gearbox to the housing. CAUTION: Assemble the small end of the boot - steering gearbox in the tie-rod groove first, and then assemble the large end of the boot - steering gearbox in the housing. NOTE: Make sure that the boot - steering gearbox is installed without unusual inflation or deflation.

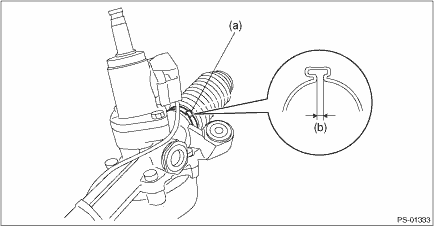

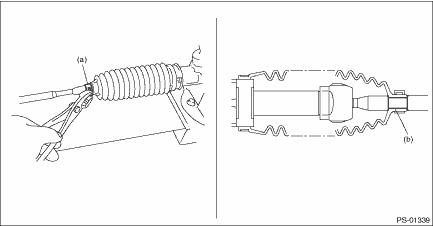

3. Using the boot clamp pliers, crimp the boot so that the clearance (b) of the band - boot (a) crimp portion becomes 2 mm (0.08 in) or less. NOTE: Use a new band - boot.

4. Fix the end of the boot - steering gearbox with clip - boot tie-rod (a). 5. After installation, check that the end of the boot - steering gearbox is installed to the groove (b) of the tie-rod.

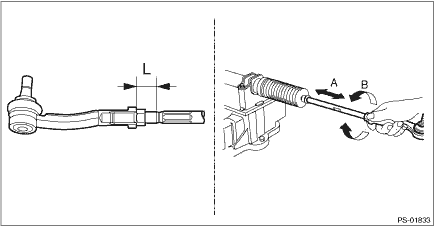

6. If the tie-rod end has been removed, screw in lock nut and tie-rod end to the threaded portion of tie-rod, and tighten the lock nut temporarily in a position as shown in the figure. Installed tie-rod length L: 27 mm (1.06 in) 7. Inspect the steering gearbox assembly as follows: (1) “A” Holding the tie-rod end, repeat lock to lock several times as quickly as possible. (2) “B” Holding the tie-rod end, turn it slowly at a radius several times as large as possible. (3) Finally, make sure that the boot - steering gearbox is installed in the specified position without inflating.

8. Remove the steering gearbox assembly from ST. |

Disassembly

Disassembly

CAUTION:When fixing the steering gearbox assembly in a vise, apply a wooden piece on the flange portion.1. Remove the tie-rod end (a) and lock nut (b) from the steering gearbox assembly.2. Remove the ...

Other materials:

Engine hood

CAUTION

When you open the engine hood,

do not stand the wiper blades up.

Furthermore, while the hood is

open, do not operate the windshield

wipers. Doing so could

result in damage to the engine

hood and wiper blades.

Be extremely careful not to catc ...