Subaru Legacy BN/BS (2015-2019) Service Manual: Inspection

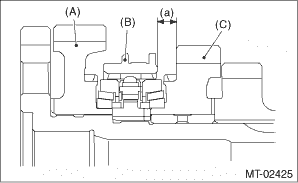

1. Check the shifter fork and fork rod for damage. Replace if it is damaged. 2. Gearshift mechanism Repair or replace the gearshift mechanism if excessively worn, bent or defective in any way. 3. Inspect the clearance between 2nd driven gear and coupling sleeve. If any clearance is not within specifications, replace the shifter fork as required. Clearance (a): 7.4 — 7.8 mm (0.291 — 0.307 in)

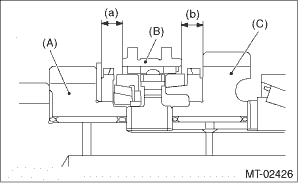

4. Inspect the clearance between the 3rd, 4th drive gear and the coupling sleeve. If any clearance is not within specifications, replace the shifter fork as required. Clearance (a), (b): 7.5 mm (0.295 in)

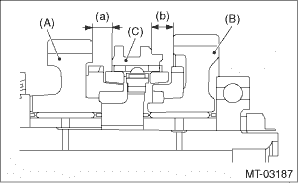

5. Inspect the clearance between 5th, 6th drive gear and coupling sleeve. If any clearance is not within specifications, replace the shifter fork as required. Clearance (a), (b): 7.5 mm (0.295 in)

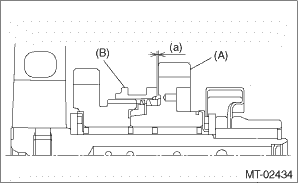

6. Check the clearance between the reverse idler gear and reverse coupling sleeve. If any clearance is not within specifications, replace the shifter fork as required. Clearance (a): 0.50 mm (0.020 in) or less

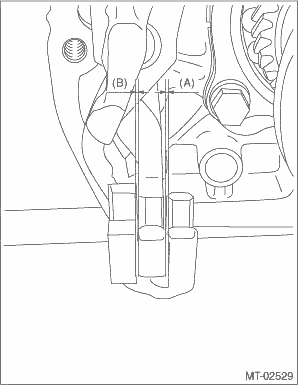

7. Inspect the rod end clearances (A) and (B). If any clearance is not within specifications, replace the rod or fork as required. Clearance (A): 1st-2nd — 3rd-4th 0.1 — 0.9 mm (0.004 — 0.035 in) Clearance (B): 3rd-4th — 5th-6th 0.2 — 1.0 mm (0.008 — 0.039 in)

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Removal

Removal

1. Remove the manual transmission assembly from the vehicle. Manual Transmission Assembly > REMOVAL2. Remove the back-up light switch and the neutral position switch. Switches and Harness > REMOVAL3 ...

Installation

Installation

1. Install the 1st-2nd fork rod to the 1st-2nd shifter fork through the hole on the rear of the transmission case.2. Align the holes on the 1st-2nd fork rod and 1st-2nd shifter fork, and drive the str ...

Other materials:

Dtc b27a7 trunk/rear gate internal antenna open

DTC DETECTING CONDITION:When open circuit occurs in the harness between keyless access CM and rear interior antenna.TROUBLE SYMPTOM:Keyless access system does not function. (when the access key is in the rear area of the passenger room (in the luggage room or trunk))CAUTION:For replacement procedure ...