Subaru Legacy BN/BS (2015-2019) Service Manual: Installation

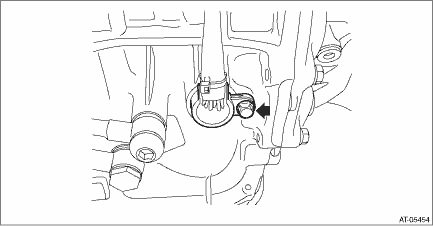

1. Install the harness clip to the transmission assembly. 2. Insert the transmission harness bushing into the round hole on the transmission case and install the bolt. NOTE: • Use new O-rings. • Do not impact or bend the transmission harness because it has the oil temperature sensor inside. Tightening torque: 5 N·m (0.5 kgf-m, 3.7 ft-lb)

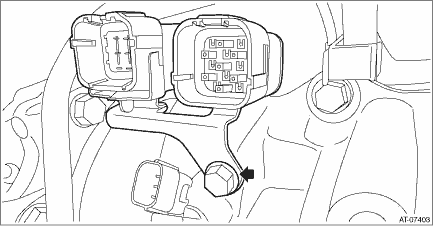

3. Install the control valve body. Control Valve Body > INSTALLATION 4. Install the transmission harness connector and inhibitor harness connector to the harness stay. 5. Install the transmission harness stay. Tightening torque: 16 N·m (1.6 kgf-m, 11.8 ft-lb)

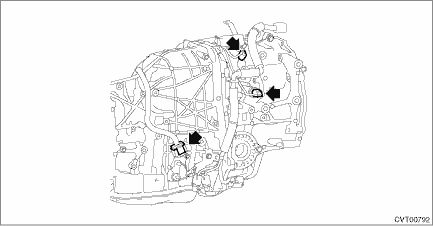

6. Connect the harness connectors to the inhibitor switch, primary speed sensor and secondary pressure sensor.

7. Connect the harness connectors to the front wheel speed sensor and secondary speed sensor.

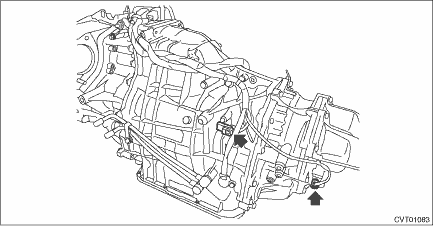

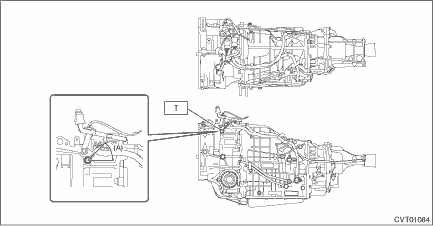

8. Install the transmission ground terminal. NOTE: Install the transmission ground terminal at an approximately 45° angle (A). Tightening torque: 16 N·m (1.6 kgf-m, 11.8 ft-lb)

9. Install the transmission cover. Tightening torque: 8 N·m (0.8 kgf-m, 5.9 ft-lb) 10. Install the transmission assembly. Automatic Transmission Assembly > INSTALLATION |

Inspection

Inspection

1. Visually check the harness and connector for damage or crack.2. Check the harness terminal for rust, disconnection or poor contact.3. Check the continuity between harness terminals and oil temperat ...

Other materials:

Brake system warning light

WARNING

Driving with the brake system

warning light on is dangerous.

This indicates your brake system

may not be working properly. If

the light remains illuminated,

have the brakes inspected by a

SUBARU dealer immediately.

If at all in doubt about w ...